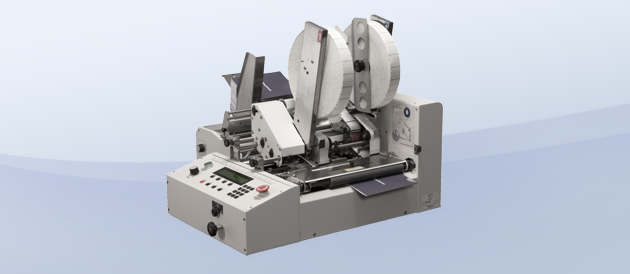

The W360 tabber is a heavy duty dual head tabletop tabber designed to apply tabs to multiple sides of the mail piece in a single pass. Offers superior material handling with precise tab placement on a variety of media sizes and thicknesses.

- Applies one, two or three tabs in one pass

- Production speeds up to 25,000 pieces per hour for single tabs and up to 10,000 pieces for triple tabs

- Superior material handling with precision registration transport guides

- Precise tab placement on a variety of media size & thickness

- Easy set-up with simple to use LCD control panel

- Applies a range of adhesive material including small labels, tabs and stamps from 3/4″ to 1-1/2″ in diameter

Technical Specifications:

- SPEED

Production Rate:

Single Tab: Up to 25,000 pieces/hr.

Double Tab: Up to 15,000 pieces/hr.

Triple Tab: Up to 10,000 pieces/hr. - MEDIA:

Size:

Minimum: 5″ W x 3.5″ L

Maximum: 11″ W x 15″ L

Thickness:

Minimum: 20# single sheet

Maximum: 1/4″

Stock: Coated, bond, recycled, card - TABS/LABELS

Types:

Tabs (single, double, triple) clear, translucent, unperfed, vertical perfed. Also applies up to 3 stamps in a single pass

Note: Clear and transulucent tabs require an “engineered backer” with registration marks for indexing. - Roll Size:

Up to 10″ diameter mounted on a 3″ core, approximately 11,000 15/16″ tabs

Backer:

Approx. 1/16″ – 1/4″ larger than tab/label, typical gap between tabs/labels is 1/8″ to 1/16″

Width:

Minimum: 3/4″; Maximum: 1 1/2″ - TAB PLACEMENT

Accuracy: +/- 1/8″ repeatability - PRODUCT CHARACTERISTICS

Dimensions: 28″W x 34″L x 26″H

Weight: 97 lbs.

Power: 115VAC, 50/60 Hz - CERTIFICATION

TUV Pending