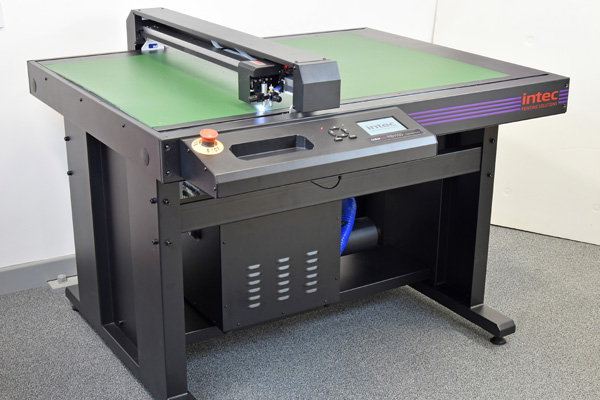

Flatbed digital die-cutting for packaging and labels

With three models in the range Intec has a flatbed cutter to suit most needs!

Digitally cut and crease card and boards of any shape with one of the range of ColorCut flatbeds on up to 600 microns.

Ideal for cartons, presentation folders, swing tickets, point-of-sale and much more!

- No dies required – cut and crease any shape on demand

- Cuts card and films up to 450gsm / 600 micron

- Dual-tool head for same time cutting and creasing

- High productivity with cutting speeds up to 1 linear metre in 1.4 seconds!

- Optical sensor accurately follows vector cut lines drawn in Adobe® Illustrator® & CorelDRAW®

- Vacuum suction media hold down table for even the smallest of items

- Available in 4 models with cutting area table sizes up to 740 x 1040mm

- Cut multiple sheets for increased productivity with smart mark detection

- Complete with dedicated cutting software

Flatbed packaging production – and sheet labels

The Intec ColorCut Flatbed series of cutters, sets new standards in cost, flexibility and speed.

Three models are on offer in the flatbed range; the FB520, with a cutting area of 520 x 350mm, the FB600 for up to 600mm x 450mm and the larger FB900.. ColorCut Flatbed cutters deliver digitally cut; card, paper, synthetics and labels of any shape, direct from your desktop. The pneumatic vacuum hold-down table secures media in place, whilst the integrated optical sensing system provides accurate registration of media, ensuring crisp, accurate crease and cut lines.

No cutting dies required

Using advanced digital contour cutting technology, the Flatbed series follows artworked cut lines drawn in Adobe® Illustrator® or CorelDRAW® – which means there is no need to purchase and wait for traditional dies to be made. Digital cutting is an ‘on-demand’ process, simply click ‘CUT’ and the sheets are produced to any shape, instantly and directly from the desktop.

Two tools enhance productivity with folding lines as well as cut lines

The Flatbed series utilises a dual tool cutting head. This enables both tools to operate simultaneously for processes such as cutting and creasing, in one operation – reducing operation time and improving productivity. Whilst the first ‘cut’ tool makes the actual full-depth cuts, the second ‘crease’ tool, scores all fold lines with its ball head, thus avoiding the exposure of paper fibres through printed areas.

Versatile and fast, sheet fed packaging production

Targeted to the light production sector, the Flatbed series cuts a typical SRA3 sheet in just 30 – 40 seconds. This enables users to easily produce anything from 10 – 1,000 SRA3 sheets per day.

Label production too

The Flatbed series also performs perfectly for sheet label cutting – cutting absolutely any shape desired.